Capabilities & Services

We maintain a strong relationship with our suppliers to keep a constant flow of raw materials to our plant. This allows us to meet our customers' critical demands and expectations, even on short notice or rush jobs. We can partner with you to reduce your overall manufacturing cost and increase profitability by tailoring the right solution that fits your needs.

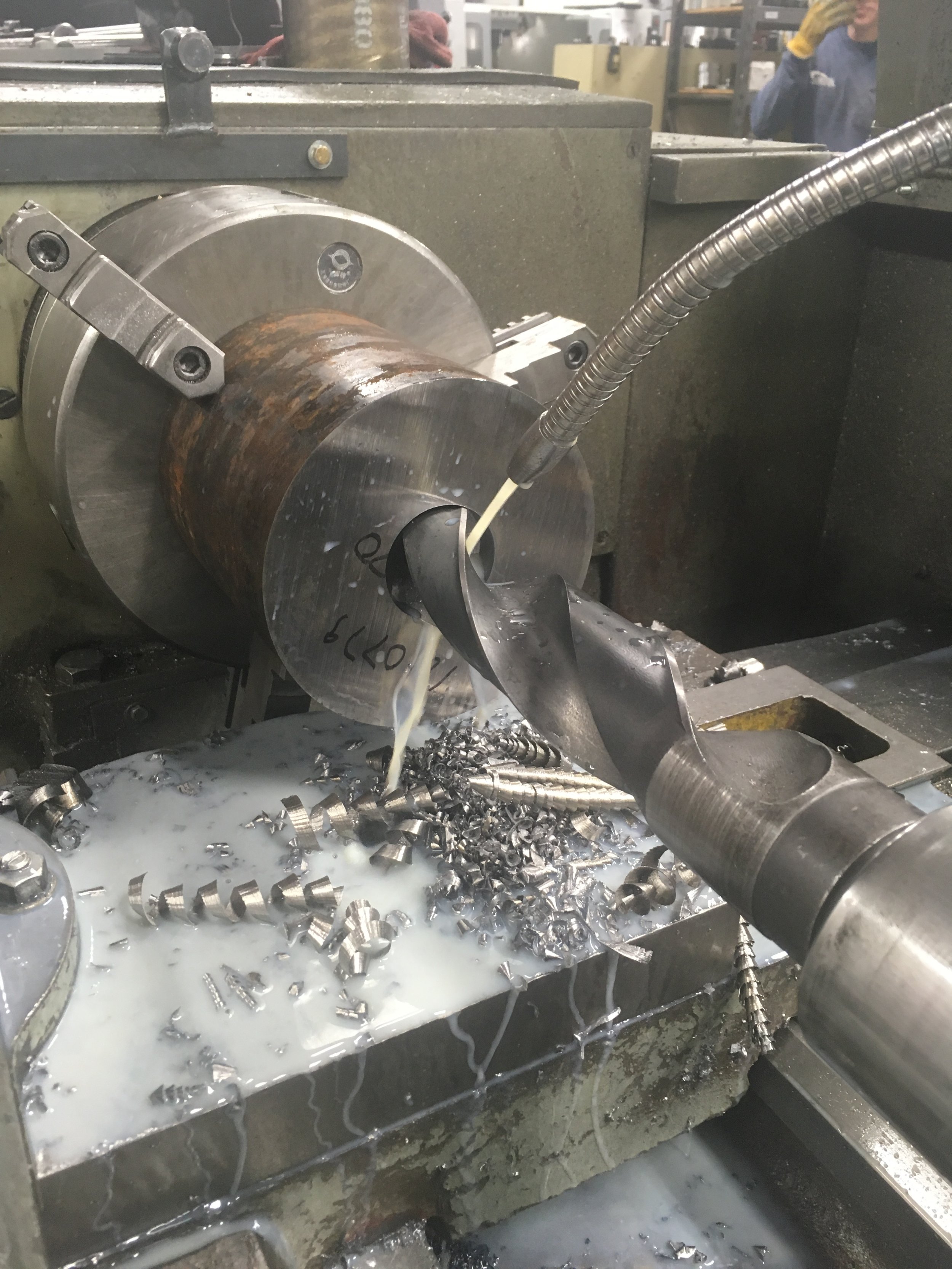

Machining

HAAS CNC Vertical Mills up to 32"x84” capacity with 4-Axes

CNC Lathe capacity up to 22" diameter with 36" long/live tooling

Surface Grinder 12"x36" & 12”x24” Steel and Stainless Steel

Manual Lathe 0" to 49" Diameter up to 37.5' long (turning, boring, facing, grooving, drilling, tapping)

Vertical Manual Milling

Vertical Boring Mill - 120’ Swing

Heavy Duty Horizontal Milling 4” with Rotary Table 18,000 table capacity, 64”x64” capacity

Flow WaterJet 6'x14' 60k pump with SmartStream technology to eliminate taper

Router Multicam CNC 80”x144” with tool changer

CNC Horizontal Boring Mill 4-Axes

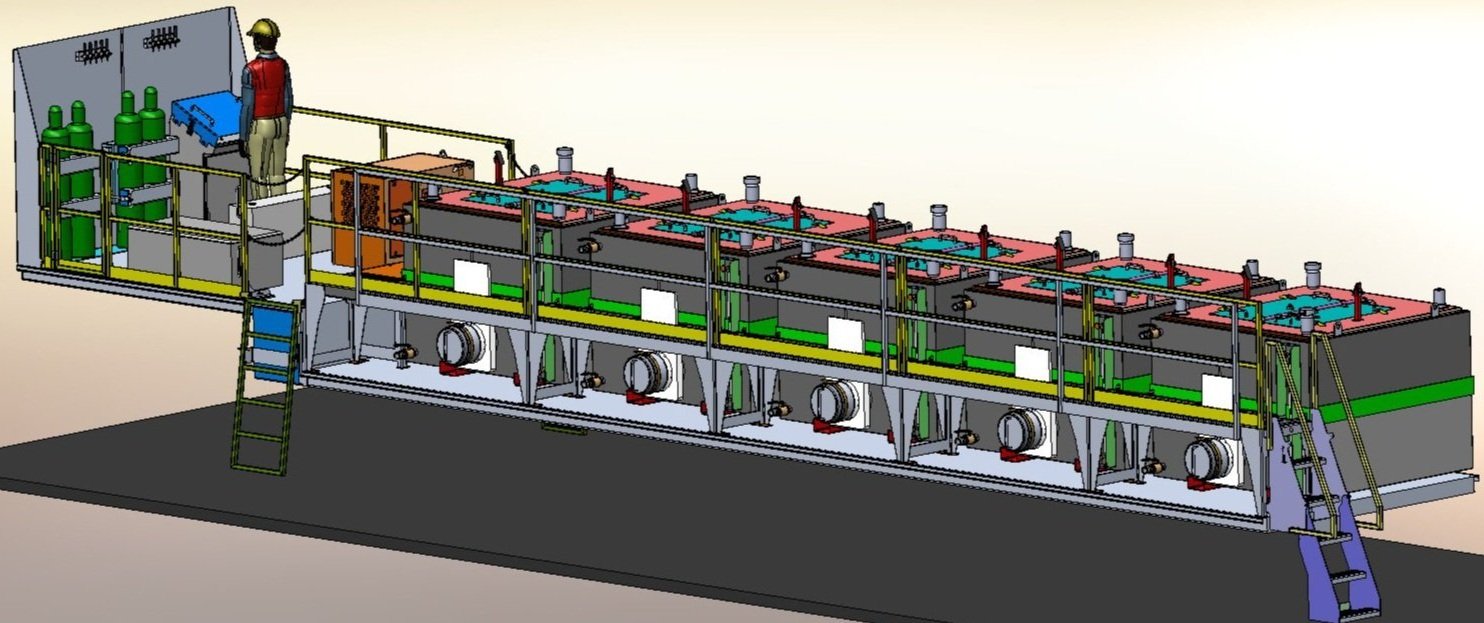

Fabrication

CNC oxy-acetylene 6'x12' capacity

Press Brake 12'x32, 5 Ton capacity

CNC Press with Back Gauge 16'x100 Ton

Hydraulic Sheer with Back Gauge 1/4"x12' & 1/2"x12'

Piranha Ironworker 50 & 90 Ton

Saw 18”x12”

Rolls 4'x1/4"

Plate Rolls 5/8"x6'

Vertical Saw 18"x22"

Large Capacity Radial Drill

Pipe and Tube Bender – up to 3” diameter

Submerged Arc Welding - hardface and buildup

Welding Positioners to 36”

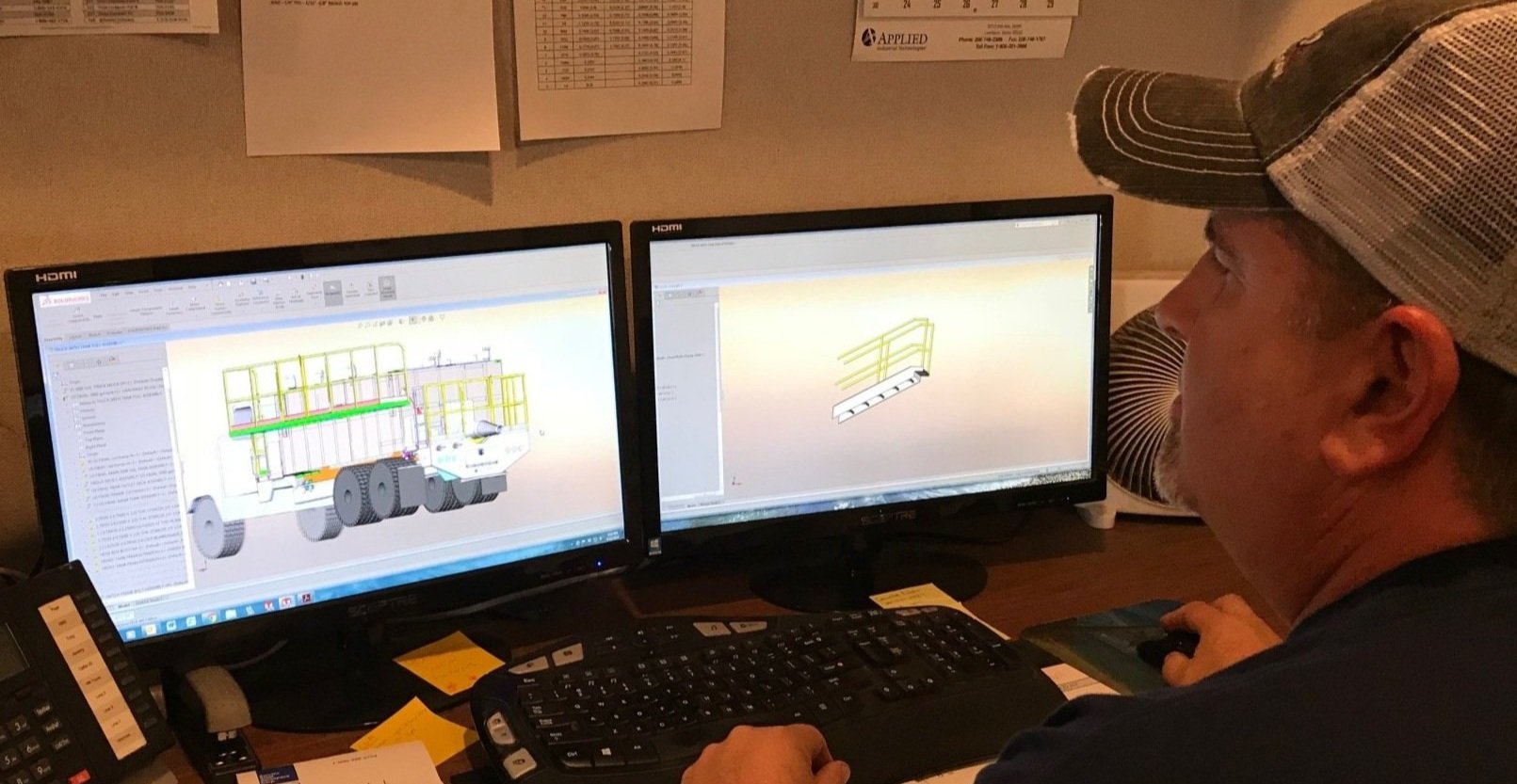

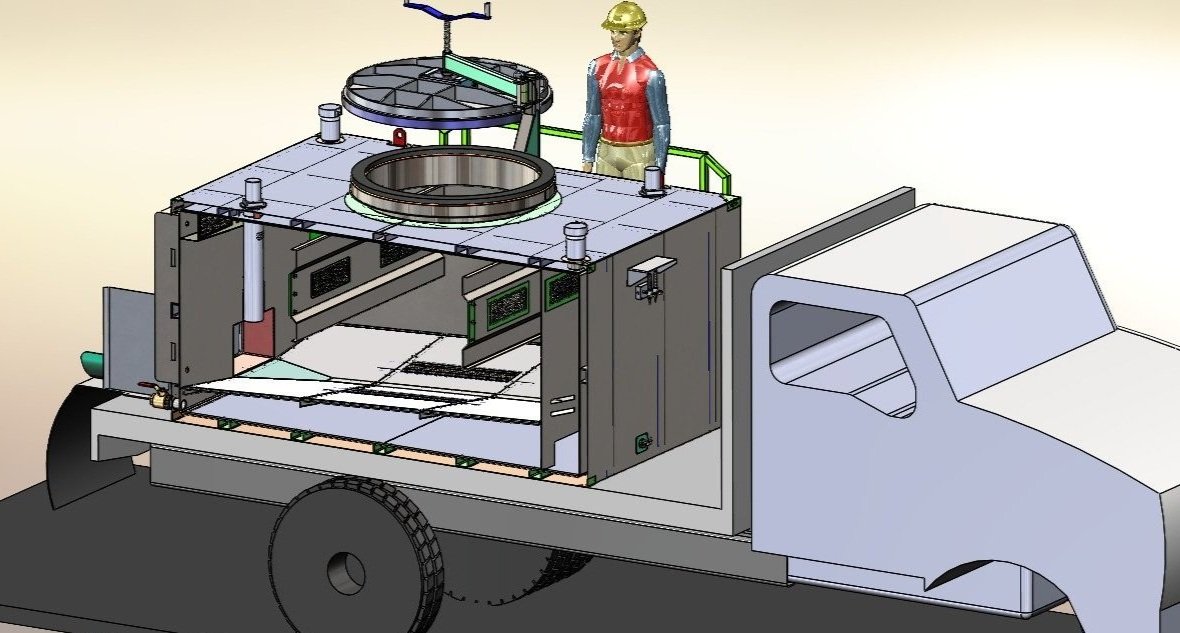

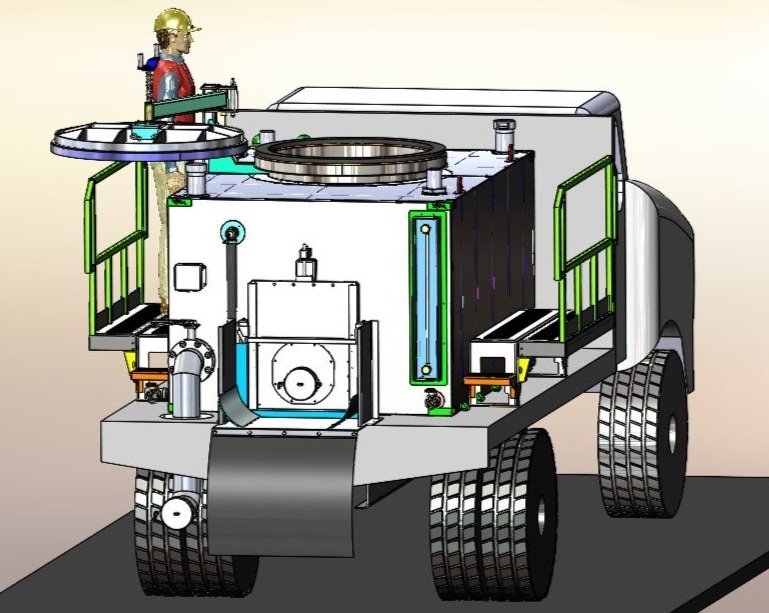

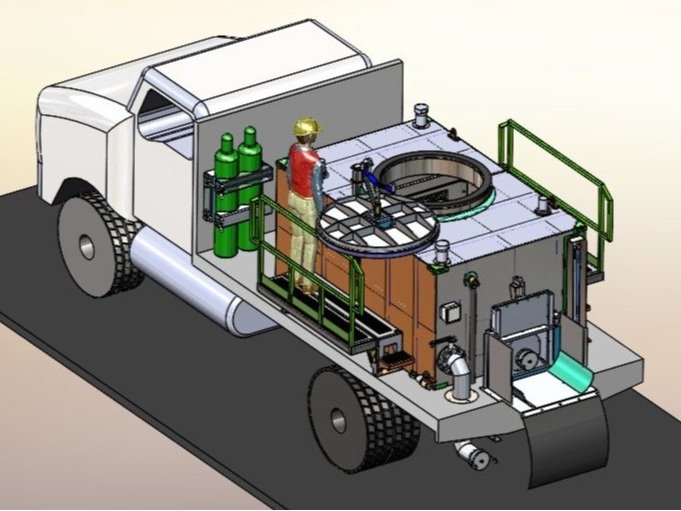

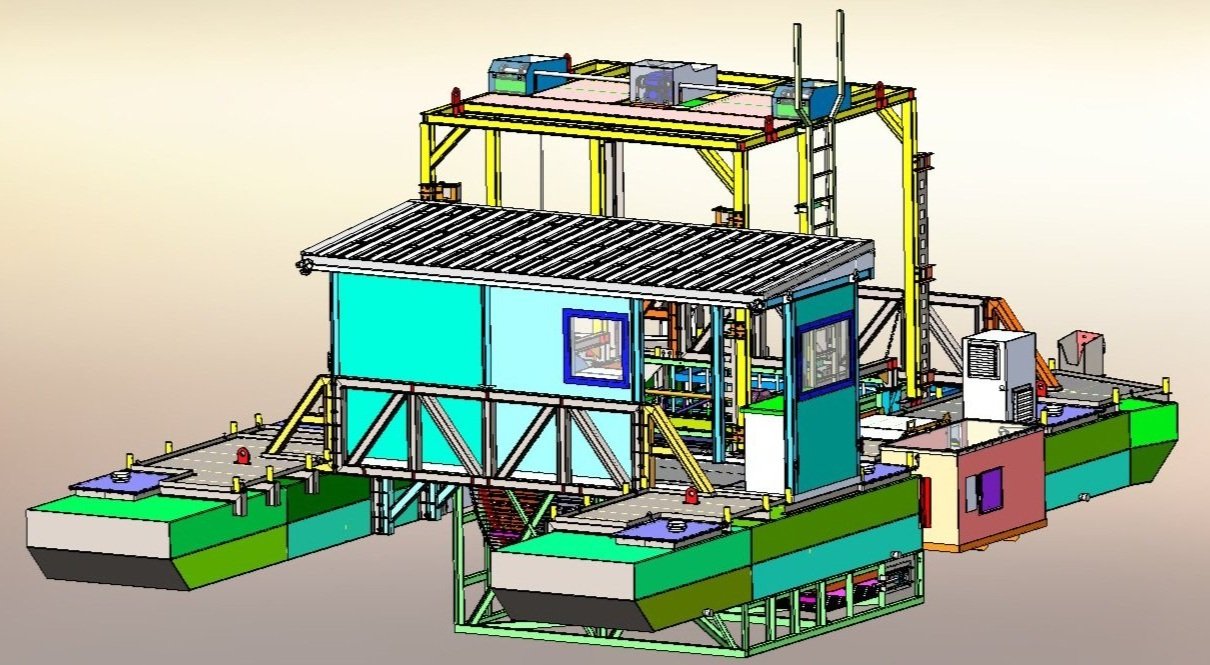

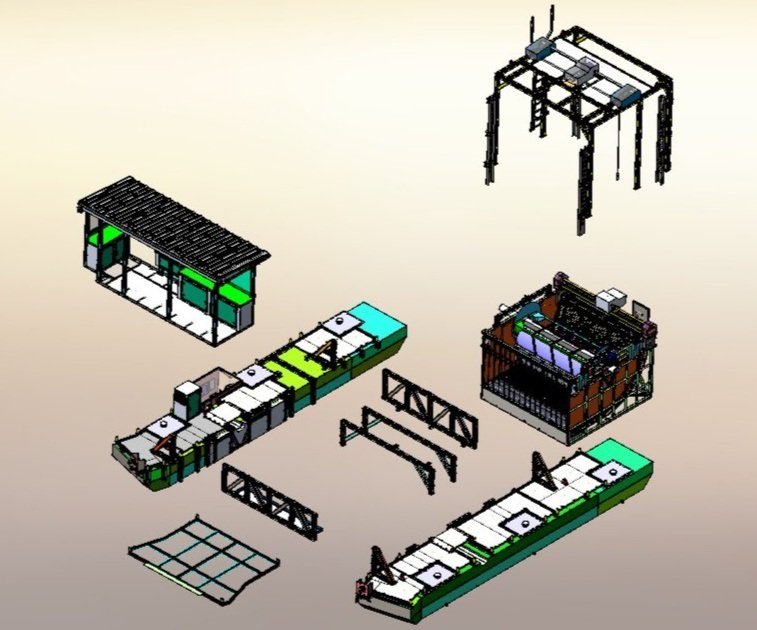

Full service

design department

SolidWorks

CAMWorks

Prototyping

Reverse Engineering

Shop Drawings

FULL COMMERCIAL PAINT FACILITY

Sandblasting, Paint, and Coatings with temperature control.

Services

Project Estimating

Material Procurement/Inventory

Shop Drawings

Scheduling

Coordinating of Material Delivery

Production Management

Consulting

Outside Sourcing (Large Heat Treating, Flame Spray Coatings, Chrome Plating, Anodizing, Powder Coating)

welding

Our welding department consist of AWS D1.1-D1.2-D1.6 qualified welders with experiences in many different fields. Our fabrication and machining department work hand in hand to insure proper fit up and joint configuration.

MIG Welding | Stick Welding | TIG Welding

material

Steel inventory

Angle, Pipe, Tube, Plate, Bar, Channel, Sheet Metal

Aluminum

Alloy Steel

Stainless Steel

Other Non-Ferrous Alloys

Shearing | Plasma Cutting | Punching | WaterJet

Heat Treating (small parts)

punching, notching, rolling, forming

STRUCTURAL STEEL FABRICATION

Cut | Weld | Form | Layout

Building Materials

Columns | Beams | Custom Staircases - (Straight, Spiral, Angle)

Moment Frames

Handrail | Guardrail

Gates | Grills | Wrought Iron | Access Ladders