Capabilities & Services

We work closely with our suppliers to keep materials flowing, so we can meet critical demands—even on short notice. By tailoring solutions to your needs, we help lower costs and boost profitability.

MACHINING - AS9100D & ISO 9001:2015 certified Machine Shop

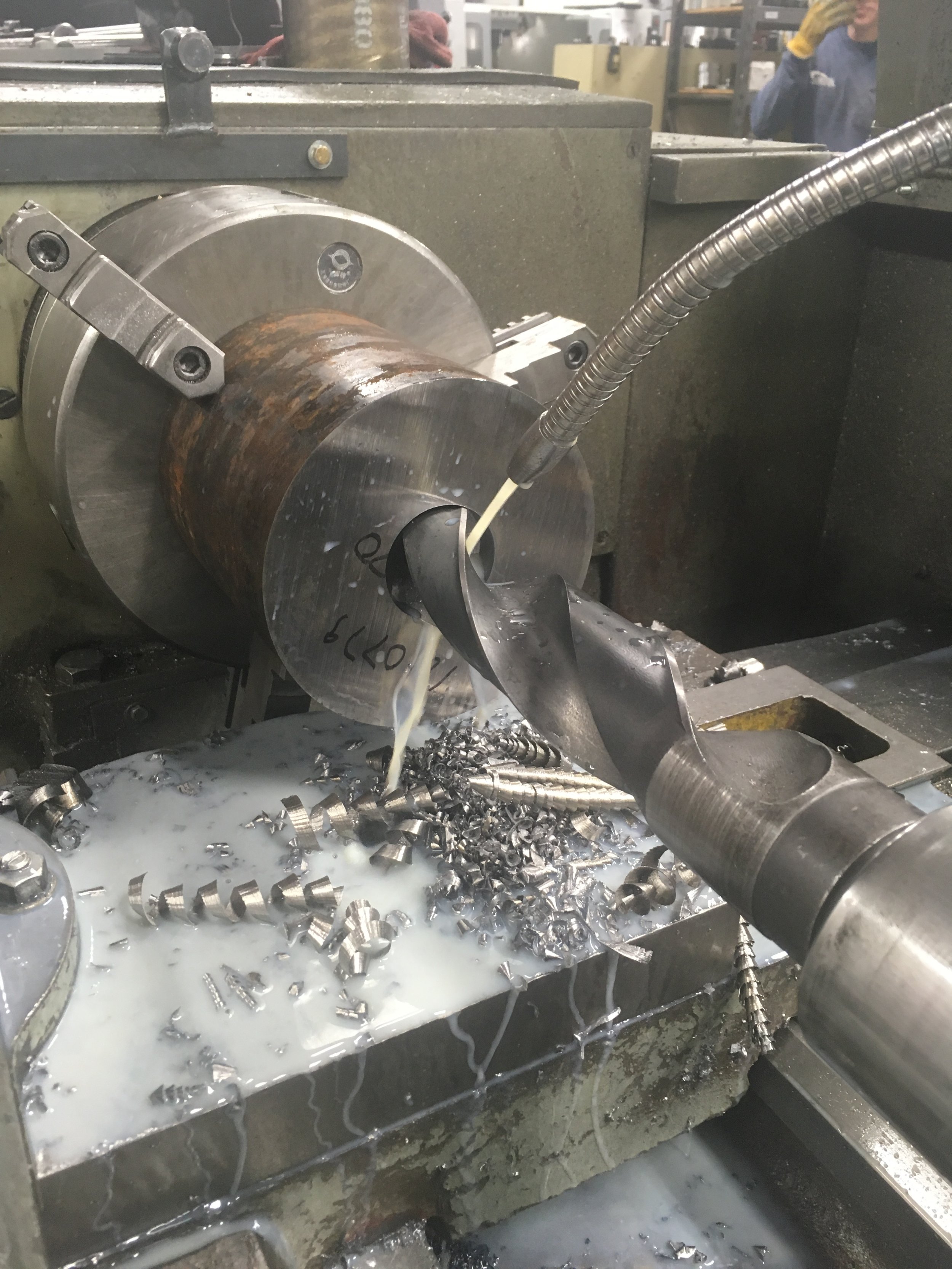

Jetco works closely with customers to ensure machining projects meet exact specifications. The Company’s robust machining capabilities, complemented by additional precision services, allow it to serve a diverse range of client needs efficiently and accurately.

Key Machining Equipment:

(5) HAAS CNC Vertical Mills, up to 32” x 84” capacity with 4-Axes

(3) CNC Lathes, up to 22” diameter and 36” long, with live tooling

(1) Surface Grinder, 12” x 24”, for steel and stainless steel

(3) Manual Lathes, 0” to 30” diameter, up to 144” long (turning, boring, facing, grooving, drilling, tapping)

(1) Vertical Manual Mill

(1) CNC Vertical Boring Mill, 84” swing

(1)CNC Horizontal Boring Mill, 4-Axes with spindle and rotary table, 13,000 lb table capacity, 64” x 64” work envelope

Jetco’s combination of advanced CNC machines and skilled operators ensures precision, efficiency, and the ability to scale machining projects to meet growing customer demand.

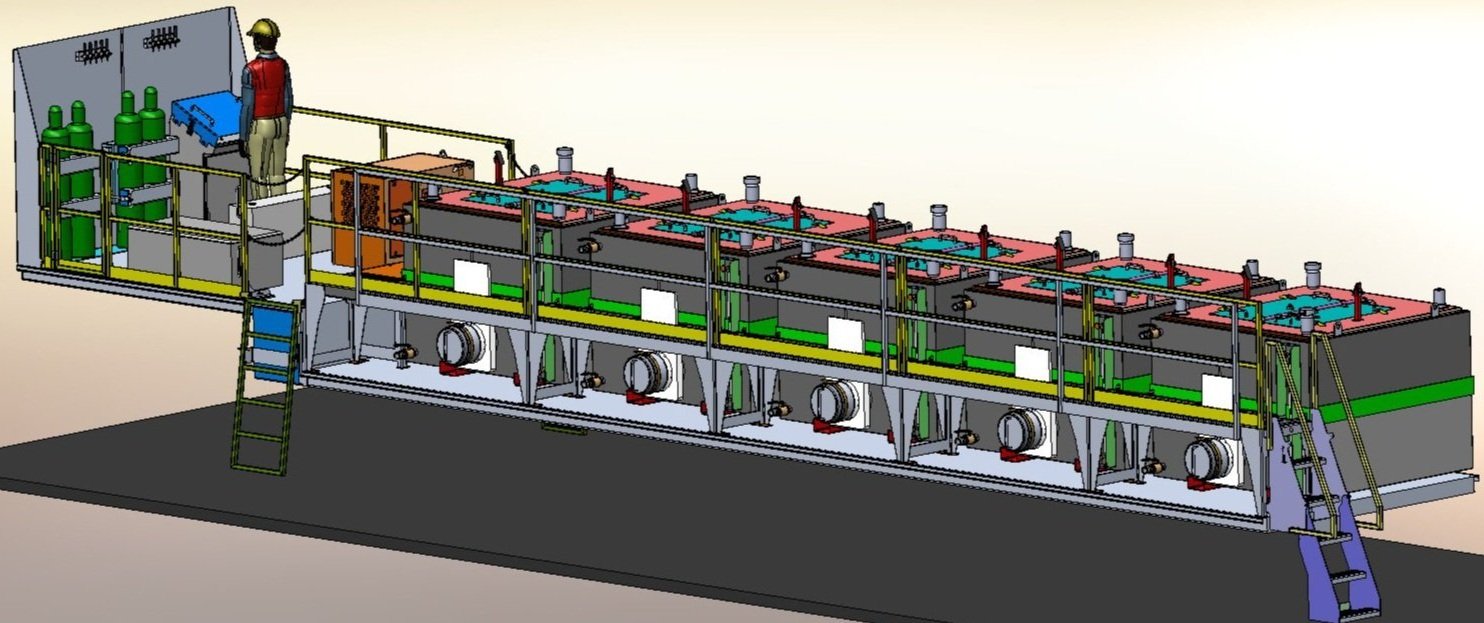

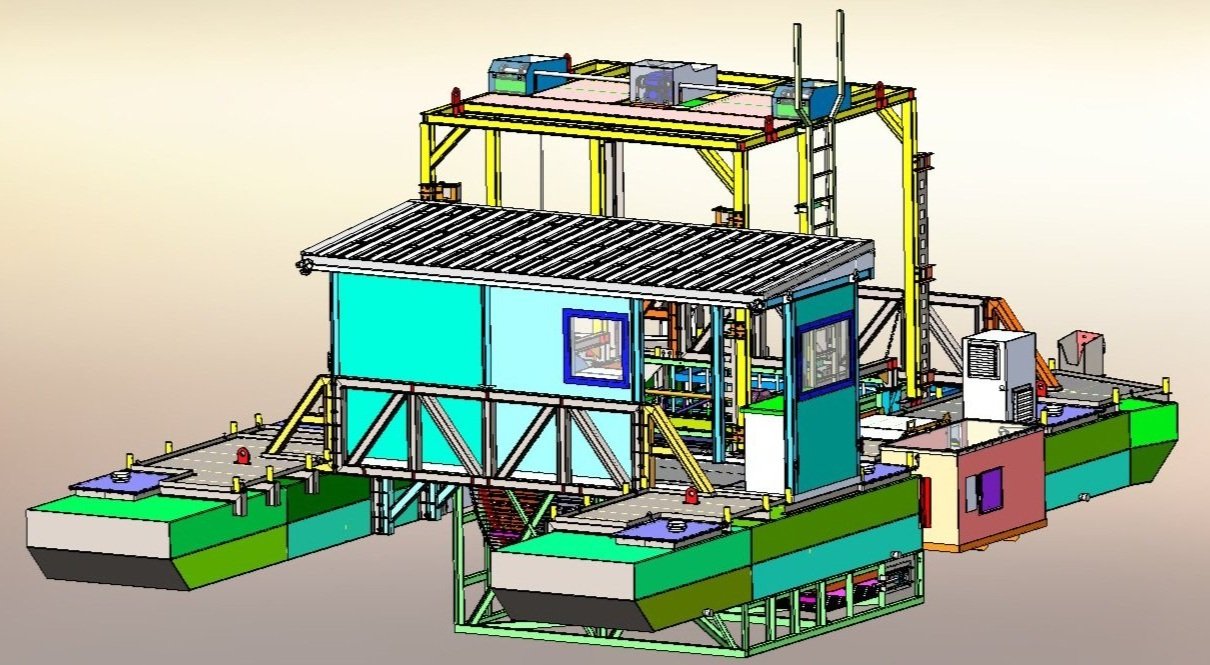

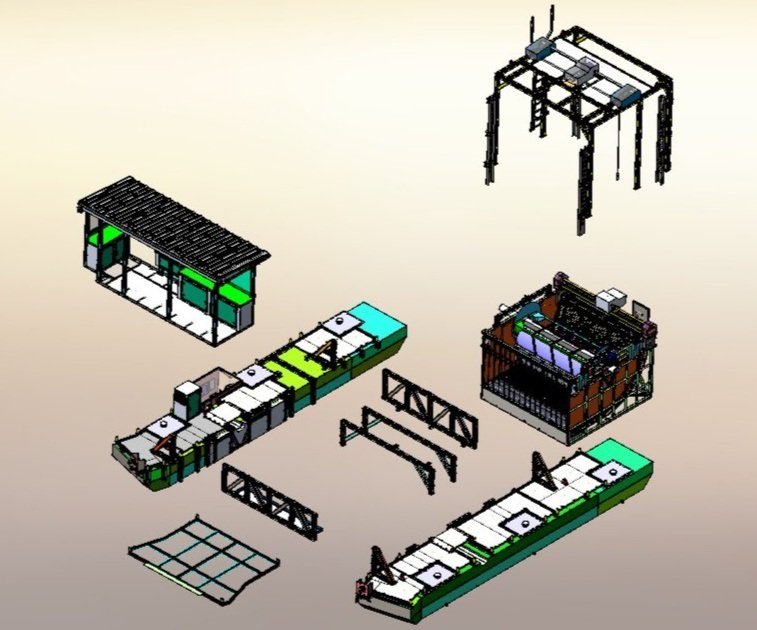

FABRICATION

Jetco’s extensive fabrication capabilities allow the Company to serve a diverse range of customers. The team collaborates closely with clients to design, budget, and fabricate products that meet precise specifications. Each product is custom-built to customer requirements, ensuring quality and timely delivery.

Key Fabrication Equipment & Capabilities:

Flow WaterJet 6’ x 13’

Multicam CNC Router with tool changer 6’ x 12’

CNC Press with 4-axis Back Gauge, 230 Ton – 14’

Hydraulic Shear with Back Gauge, 1/4" x 12’ & 1/2" x 12’

Piranha Ironworker, 50 Ton

Saw 18” x 12”

Rolls 4’ x 1/4”

Vertical Saw 18” x 22”

Pipe and Tube Bender – up to 2” diameter

Welding Positioners up to 36”

MIG, Stick, and TIG Welding

D1.1, D1.2, D1.6 qualified welders

This combination of advanced equipment and skilled personnel allows Jetco to efficiently handle complex projects, produce high-quality custom components, and scale production to meet growing customer demands.

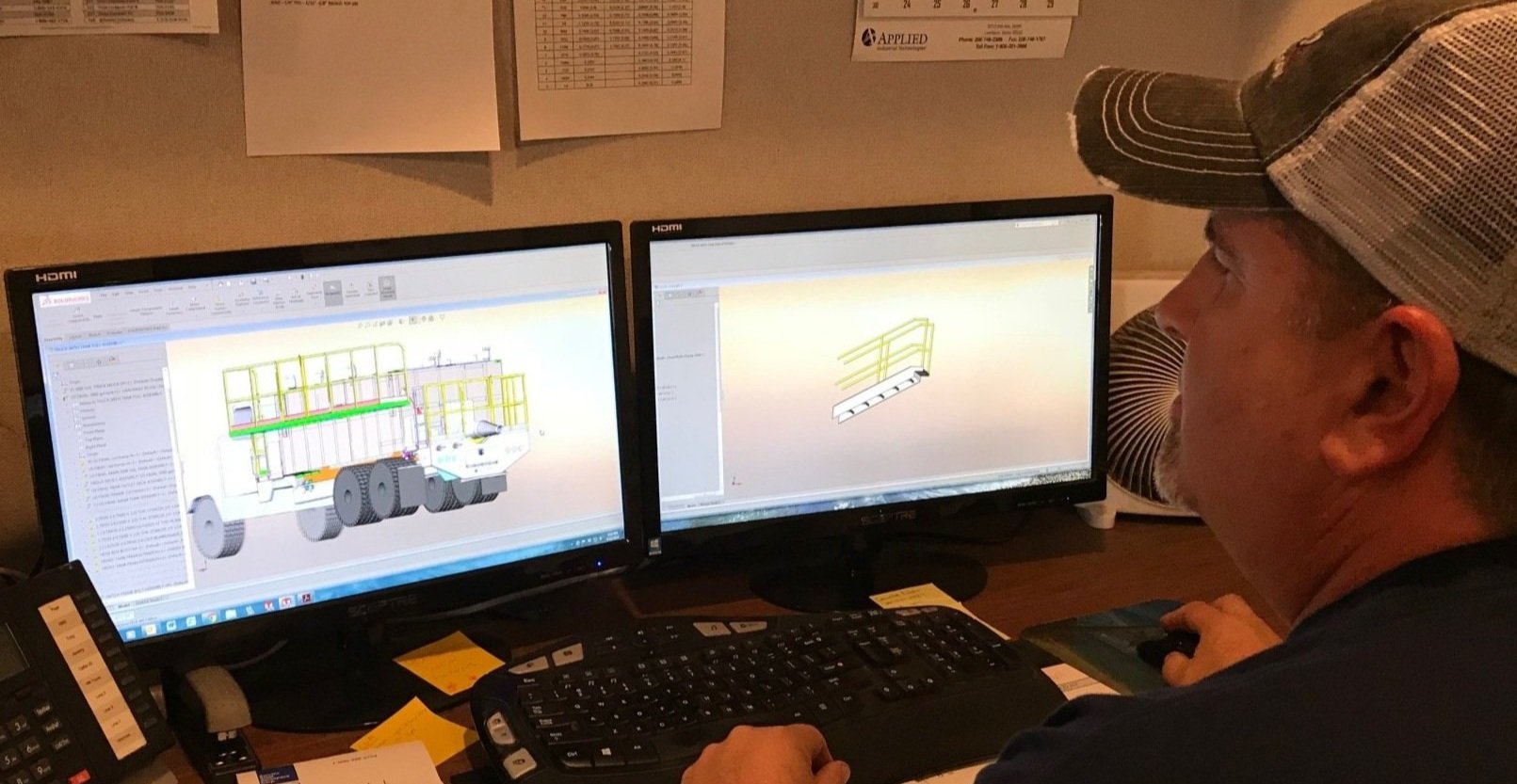

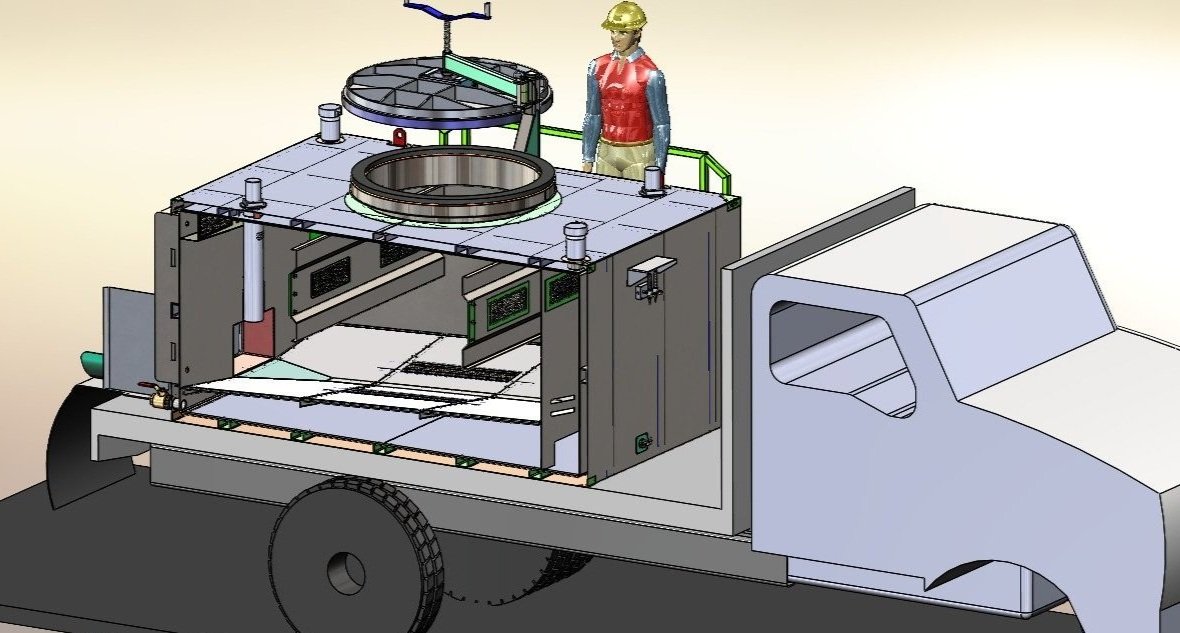

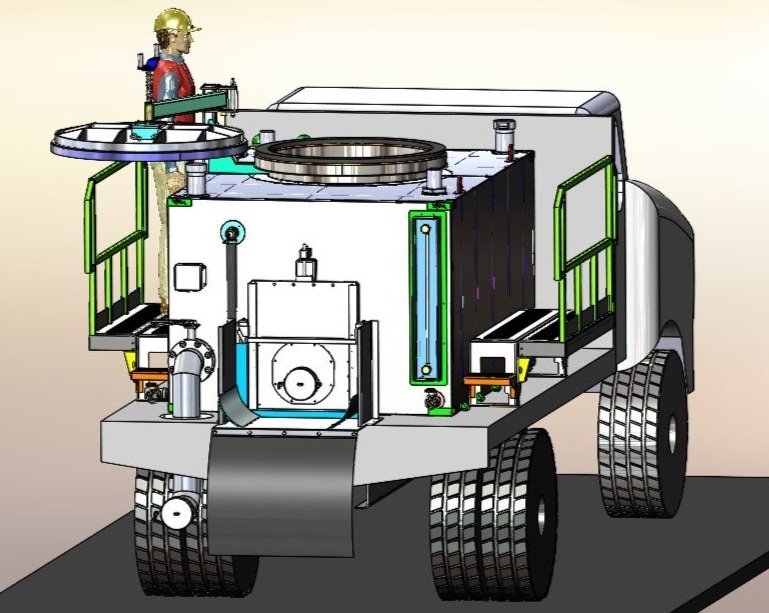

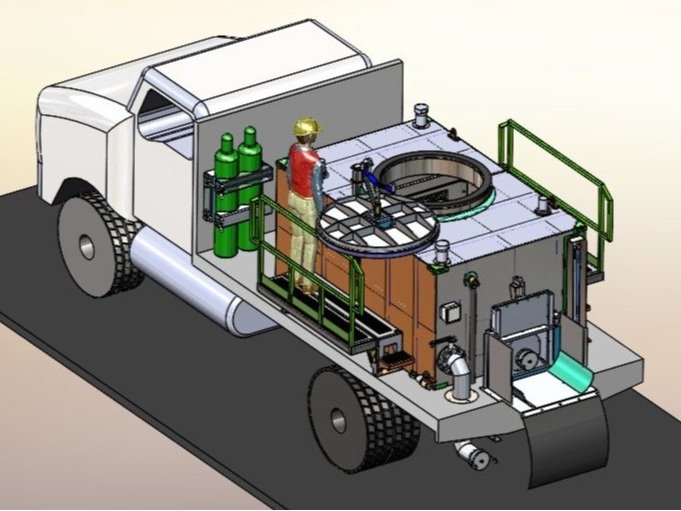

FULL SERVICE DESIGN DEPARTMENT

Jetco maintains a full-service design department to support customer projects from concept through production. The team leverages advanced software and prototyping tools to ensure precision, functionality, and manufacturability.

SolidWorks with Finite Element Analysis (FEA)

CAMWorks

Prototyping and Reverse Engineering

Shop Drawings and Solid Modeling

FULL COMMERCIAL PAINT FACILITY

In addition to machining and fabrication, Jetco offers full commercial paint capabilities, allowing the Company to complete comprehensive projects entirely in-house. This integrated approach ensures strict quality standards, precise scheduling, and greater control over final product finishes.

Key Paint Services:

Full Commercial Paint Facility

Sand Blasting

Paint and Coatings with Temperature Control

By maintaining these capabilities on-site, Jetco can deliver high-quality, turnkey solutions while minimizing project lead times and maintaining consistency across all products.

SERVICES

Project Estimating

Material Procurement/Inventory

Shop Drawings

Scheduling

Coordinating of Material Delivery

Production Management

Consulting

Outside Sourcing (Large Heat Treating, Flame Spray Coatings, Chrome Plating, Anodizing, Powder Coating)

WELDING

Our welding department consist of AWS D1.1-D1.2-D1.6 qualified welders with experiences in many different fields. Our fabrication and machining department work hand in hand to insure proper fit up and joint configuration.

MIG Welding | Stick Welding | TIG Welding

MATERIAL

Steel inventory

Angle, Pipe, Tube, Plate, Bar, Channel, Sheet Metal

Aluminum

Alloy Steel

Stainless Steel

Other Non-Ferrous Alloys

Shearing | Plasma Cutting | Punching | WaterJet

Heat Treating (small parts)

punching, notching, rolling, forming

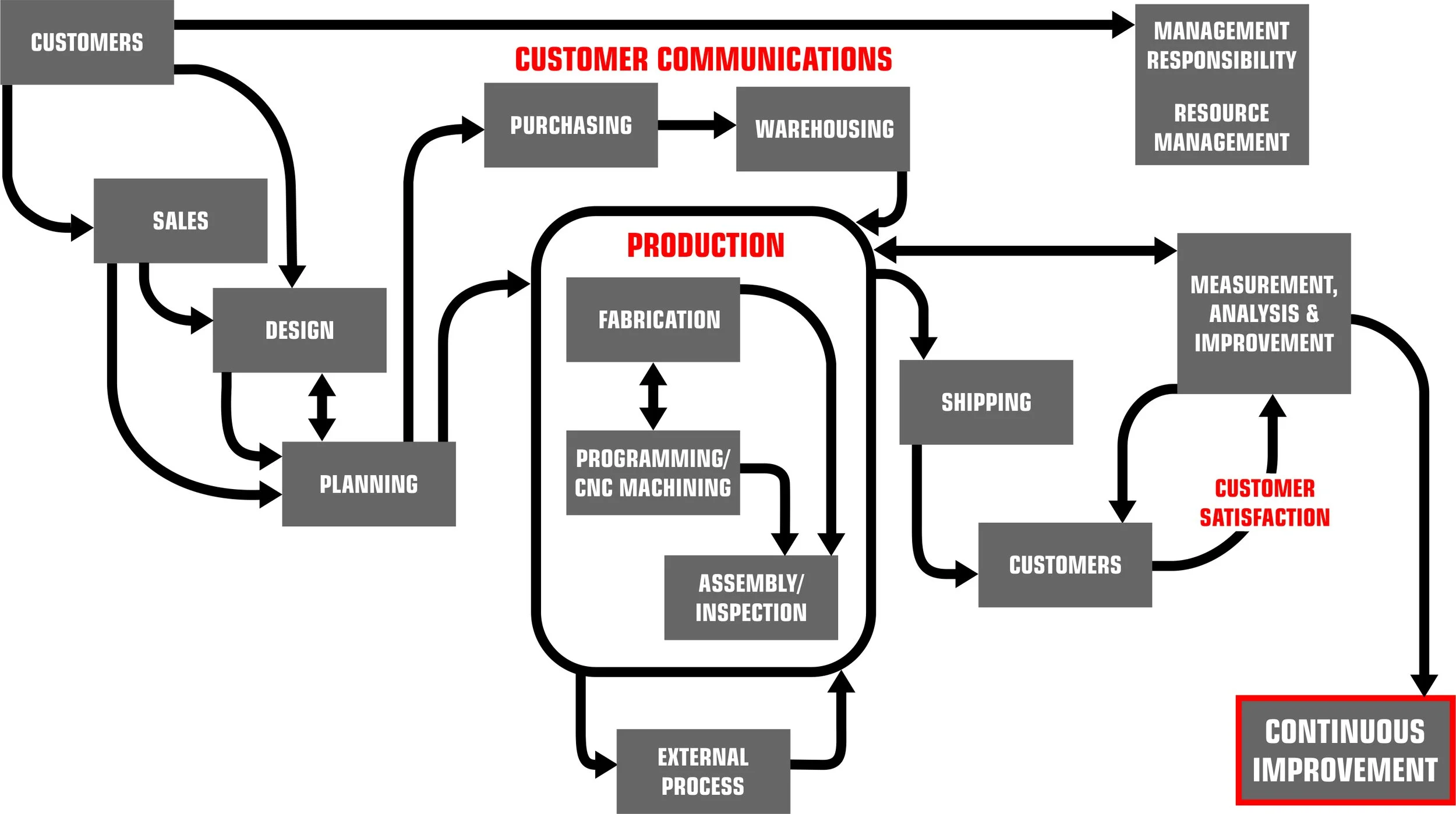

MANUFACTURING PROCESS

Jetco's design process stands out as a key competitive advantage, focusing on responsiveness to customer needs. Our in-house team effectively translates customer feedback into efficient, customized solutions. We also maintain a comprehensive database of requests, opportunities, and market insights, supported by our ProShop ERP system, which streamlines operations and enhances collaboration. Below is an outline summarizing our structured approach to new product design.

QUALITY MANAGEMENT SYSTEM

At Jetco Machine & Fabrication, quality is built into everything we do. Our AS9100D & ISO 9001:2015 certified Machine Shop reflects our commitment to delivering precision-machined components that meet the highest standards. From aerospace and automotive to medical, military, and defense, we provide mission-critical parts you can depend on. With a state-of-the-art, climate-controlled facility, we ensure accuracy, consistency, and performance every time.